In the modern home and construction sectors, particle board, as a common type of artificial panel, plays an indispensable role. With its unique manufacturing process, diverse classification methods, and wide-ranging applications, it has gained favor in the market.

The origins of particle board can be traced back to late 19th-century Europe, marking the beginning of its exploratory journey. Later, with the emergence of synthetic resin adhesives and continuous improvements in production technology, particle board gradually matured. After years of development, China has now become one of the world’s largest producers of particle board.

The production process of particle board is rigorous and complex. First, materials are prepared: raw materials are chipped into particles and stored; next, in the drying and sorting stage, the dryness and uniformity of the particles are ensured; in the subsequent gluing stage, the particles are evenly coated with adhesive; during the mat forming and hot-pressing stage, a continuous slab strip is formed and pressed; after that, multiple rounds of inspection and processing are carried out in the post-treatment stage; finally, in the sanding and cutting stage, the particle board core is made and cut into the final product.

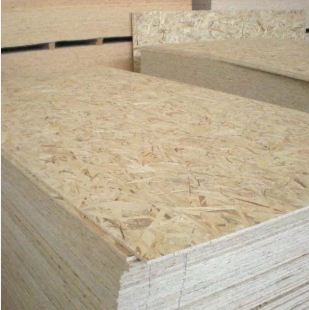

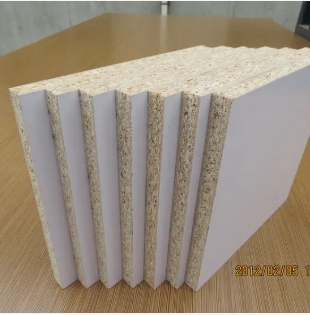

Particle board comes in various types according to different classification methods. By manufacturing process, there are flat-pressed particle board and extruded particle board; by surface treatment, they are divided into uncoated particle board and faced particle board; by application scenario, they can be categorized into indoor particle board and outdoor particle board; by material, there are wooden particle board and non-wood particle board.

Particle board boasts numerous advantages. It has a smooth surface with realistic textures, making it aesthetically appealing and suitable for various veneering treatments. It has a uniform bulk density and minimal thickness error, with a relatively low amount of adhesive used in production, resulting in a higher environmental protection coefficient. The granular structure with intersecting layers inside gives it basically the same performance in all directions, good transverse load-bearing capacity, and excellent sound absorption and insulation properties.

In terms of applications, particle board is extremely versatile. In construction, it can be used to make interior wall panels, exterior wall panels, floors, roofs, etc. In furniture manufacturing, it is commonly used in the production of wardrobes, bookcases, kitchen cabinets, and other furniture. Additionally, it is used for counter tops, floor underlayment, housing planks, stair treads, and partitions, among others.

Post time: May-21-2025